Sektörde

50

Yıllık

Deneyim

Deneyim

2.500+

Memnun Müşteri

25.000+

Başarıyla Tamamlanmış Proje

80+

80'den Fazla Ülkede Hizmet Ağı

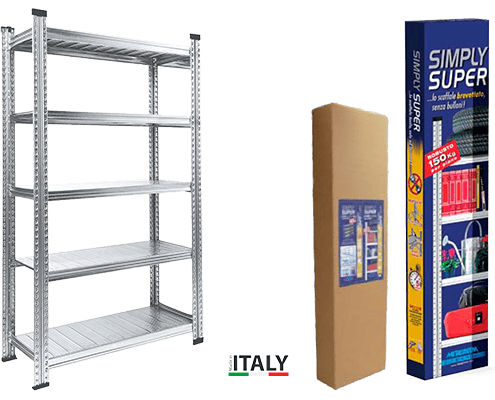

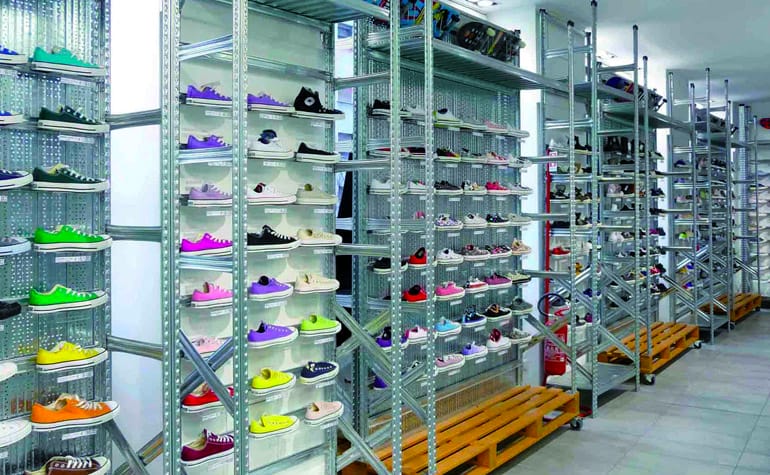

150 KG Taşıma KapasitesiKutudan çıkan ürününüz raf başına 150 kg'a kadar taşıma kapasitesine sahiptir.

%100 Paslanmaz GalvanizGalvaniz çelik ile ürününüzü değiştirmek zorunda kalmaz, uzun yıllar kullanırsınız.

Çevre Dostu Eko ÜretimTüm üretim süreçleri doğa dostudur, çevreye zarar vermez.

INTERLOCK Kilit SistemiTraverslerin ve rafların yanlışlıkla kaldırılmasını önlemek için güvenli emniyet pimleri.

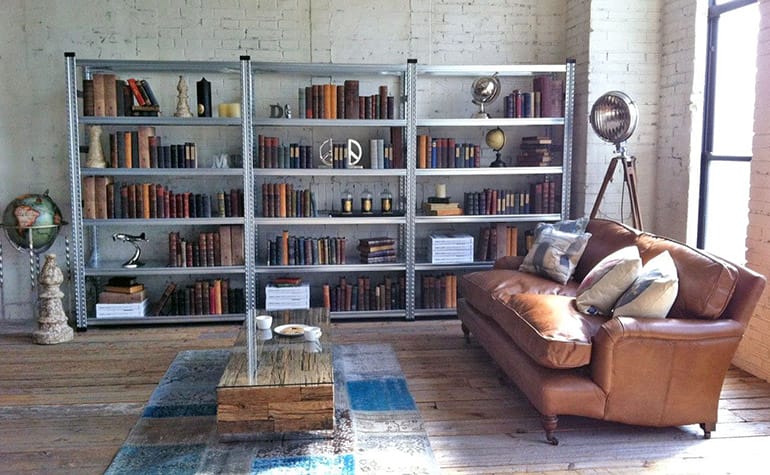

Nerede kullanmak istiyorsanız orada...